The K25LP throttle control is a vital component in managing engine speed and ensuring optimal performance for various types of machinery. Designed for precision, safety, and ease of use, the K25LP throttle control plays a crucial role in industries that rely on heavy equipment, industrial machinery, and other systems requiring accurate throttle management. This article will explore the features, benefits, installation, maintenance, and troubleshooting tips for the K25LP, providing a comprehensive understanding of its value in enhancing engine management.

What is the K25LP Throttle Control?

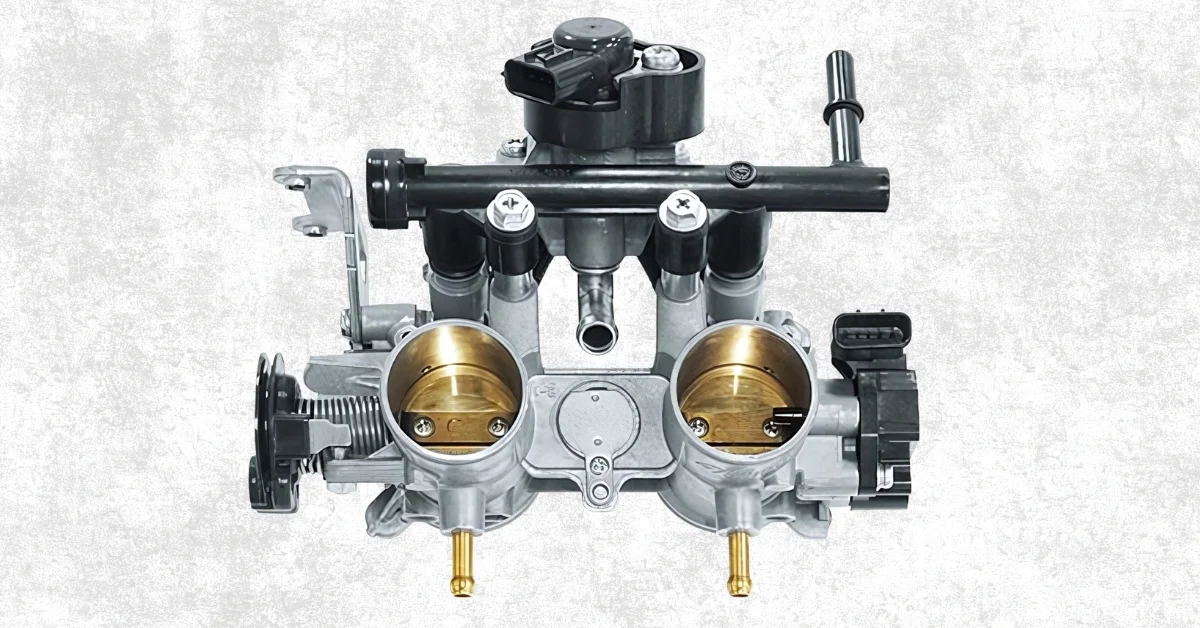

The K25LP throttle control is a device engineered to regulate the speed and power output of engines, primarily in heavy machinery and industrial equipment. Its primary purpose is to allow operators to precisely control the engine’s throttle, adjusting the amount of fuel and air mixture entering the combustion chamber to achieve the desired speed and efficiency.

This throttle control is versatile and can be found in various applications, such as construction vehicles, agricultural equipment, marine engines, and other industrial machines where precise engine control is critical. By ensuring smooth operation and responsive performance, the K25LP is essential for maintaining the functionality and safety of equipment in different environments.

Key Features

Precision Adjustment

The K25LP offers precise control over engine speed, allowing operators to fine-tune performance according to the specific needs of their application. This accuracy ensures smooth operation, reducing wear and tear on the engine and enhancing fuel efficiency.

Robust Construction

Built to withstand challenging conditions, the K25LP features high-quality materials that ensure durability and longevity. Its robust construction is designed to handle the wear and tear associated with heavy use, making it ideal for environments where reliability is a priority.

Ergonomic Design

The throttle control is designed with user comfort in mind. Its ergonomic handle reduces operator fatigue during prolonged use, allowing for smooth and comfortable operation. The design also minimizes hand strain, which is particularly beneficial in applications where frequent throttle adjustments are necessary.

Safety Mechanisms

The K25LP throttle control includes several safety features, such as throttle locks and return springs. These mechanisms help prevent accidental acceleration or deceleration, enhancing overall safety by ensuring that the throttle remains in the desired position during operation.

Benefits of Using the K25LP Throttle Control

Improved Performance

The precision adjustment capability of the K25LP throttle control contributes to smoother engine operation, reducing vibrations and mechanical stress. This leads to a longer engine lifespan, improved fuel efficiency, and overall better performance of the machinery.

Enhanced Safety

With its built-in safety features, the K25LP reduces the risk of accidents due to unintended throttle movements. The throttle lock and return spring mechanisms ensure that the throttle returns to its default position if released, preventing sudden changes in speed that could cause accidents.

User-Friendly Operation

The ergonomic design ensures that the K25LP is easy to use, even during extended periods of operation. This reduces operator fatigue and increases productivity, making it a preferred choice for professionals who require reliable and comfortable throttle control.

Versatility

The K25LP is suitable for a wide range of applications, from construction machinery to agricultural equipment, and can be used in various environments. Its adaptability makes it an ideal choice for operators who need a dependable throttle control solution.

Installation and Setup

Installing the K25LP throttle control is a straightforward process that can be completed in a few steps:

Preparation

- Gather all necessary tools and ensure the equipment is powered off.

- Review the manufacturer’s installation guide for specific instructions related to your machinery.

Mounting the Control

- Secure the throttle control unit in the designated location, ensuring it is within easy reach of the operator.

- Use the appropriate fasteners to attach the unit securely, avoiding any loose connections that could affect performance.

Connecting the Cables

- Attach the throttle cable to the control lever, ensuring it is properly aligned and tensioned.

- Connect any additional electrical wiring, such as safety interlocks or sensors, according to the manufacturer’s specifications.

Testing the Setup

Once installed, test the throttle control by gradually adjusting the lever to verify that it provides smooth and responsive control over the engine.

- Make any necessary adjustments to cable tension or alignment to ensure optimal performance.

- Maintenance Tips for Prolonging the Life of Your K25LP Throttle Control

- To maintain the K25LP throttle control’s efficiency and extend its lifespan, regular maintenance is essential:

Regular Cleaning

Keep the throttle control clean by regularly removing dirt, dust, and debris. This prevents buildup that could interfere with smooth operation.

Lubrication

apply appropriate lubricants to the moving parts of the throttle control to ensure smooth motion. Lubrication also helps prevent rust and corrosion.

Inspection for Wear and Tear

Periodically inspect the throttle control for signs of wear, such as frayed cables, cracked housings, or loose connections. Replace any damaged components immediately to avoid operational issues.

Common Issues and Troubleshooting

Here are some common issues that may arise with the K25LP throttle control and how to troubleshoot them:

Stiff or Unresponsive Throttle Movement

This could be due to dirt buildup or lack of lubrication. Clean the throttle control and apply lubricant to ensure smooth movement.

Throttle Fails to Hold Position

Check the throttle lock mechanism for wear or damage. Ensure that the lock engages properly when set and replace any worn parts as needed.

Erratic Engine Speed

Inspect the throttle cable for kinks or damage. Ensure it is properly tensioned and aligned. Also, check for any electrical faults in the control system.

Conclusion

The K25LP throttle control is a critical component for achieving precise engine management in various machinery applications. Its combination of robust construction, ergonomic design, and essential safety features makes it a reliable and versatile choice for professionals across different industries. By understanding its features, benefits, and maintenance requirements, operators can ensure that their equipment performs optimally and safely, leading to improved productivity and reduced downtime.

FAQs

What types of machinery are best suited for the K25LP throttle control?

The K25LP throttle control is ideal for heavy machinery, industrial equipment, agricultural vehicles, and marine engines.

How often should the throttle control be inspected for maintenance?

Regular inspections should be conducted every three to six months, depending on usage frequency and operating conditions.

Can the K25LP throttle control be used in extreme weather conditions?

Yes, its robust construction is designed to withstand a range of environmental conditions, but regular maintenance is recommended to ensure consistent performance.